Understanding what your reading is incredibly important when you are learning about 3D Printers.

When I first started researching 3D printers I kept coming across the acronyms FFF and FDM. The machines looked the same and I found it perplexing and a bit confusing. I quickly found that FFF stands for Fused FIlament Fabrication and FDM stands for Fused Deposition modeling, but what’s the difference? Let me clear the air right now. There is no difference between FFF and FDM. None! Other than a trademark issue. Think of Kleenex and tissue paper as an easy example. With that out of the way let’s dive into what these two terms really are.

Why Two Terms?

When the technology was initially developed Stratysys Inc. trademarked FDM. As 3D Printing gained popularity with makers the RepRap community created FFF so people could discuss the technology without fear of infringing on trademarks. Again, the actual processes involved in creating a 3D print for FFF and FDM is exactly the same. There is no difference between these two technologies.

Which Term Should I Use FFF or FDM?

For my part, I primarily use the term FFF and only use FDM in conjunction with FFF for clarity.

Unfortunately for beginners, writers use FDM frequently in literature, tech spec documents and when discussing materials. As the 3D printer community begins to get into the hands of the masses the confusion will only grow.

It is up to all of us to make sure we are careful with the terminology we use or we will have more and more people wondering if the supplies listed for use with FDM 3D printers will work with their FFF 3D printers. (Hint: They will.)

What is Fused Filament Fabrication (FFF) Anyway

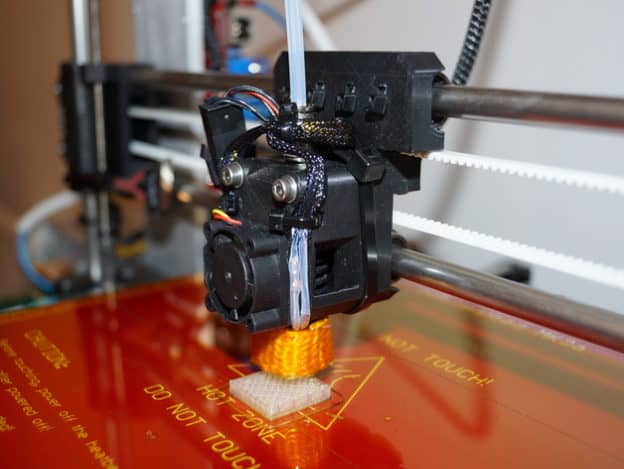

OK, so we say FFF, but what is it really? Fused Filament Fabrication is a form of additive manufacturing. At its heart, it’s a process that takes any material, in our world PLA or ABS filament usually, and lays it down.

The printer adds layers and through heat or adhesion causes the layers to “fuse” together. This is why you commonly see the layers in 3D prints. It is also the reason you will need to have support structures within your prints to help support each layer as it is added.

As you may have guessed, the FFF process does have a potential weakness. Because layers are stacked one on top of the other they are weaker in one direction than another. There are ways to overcome this obstacle in choosing how you print. You can change up your patterns on your infill to add strength.

That Was Painless, What’s Next?

With that simple question out of the way, you might be thinking it’s a closed issue right? Well, that depends. Chances are if you landed on this page you had some questions and likely still have more about the basics of 3D printing.

I know when I had this question and found my answers I too had more questions. That’s the whole reason I created this site.

If you are really new to 3D Printing perhaps an article about the anatomy of a 3D printer, will help you wrap your head around the parts of a 3D Printer. If the technical aspects interest you more and you are thinking about buying a 3D Printer soon you need to see my 3D Printer Buyer’s Guide where I break down the most common specifications and what they mean..

Maybe you’re a big idea person, and you want to know about the flow and process of 3D printing. In that case you could start with an article about how the 3D printing Process works from start to finish.

Ok, that was quick, wasn’t it? Everything should be clear now. It seems like a silly topic to tackle, but I’ve noticed this question around, and it really needed to be addressed.

Now that you have more knowledge you I’ll send you back out into the world.